-

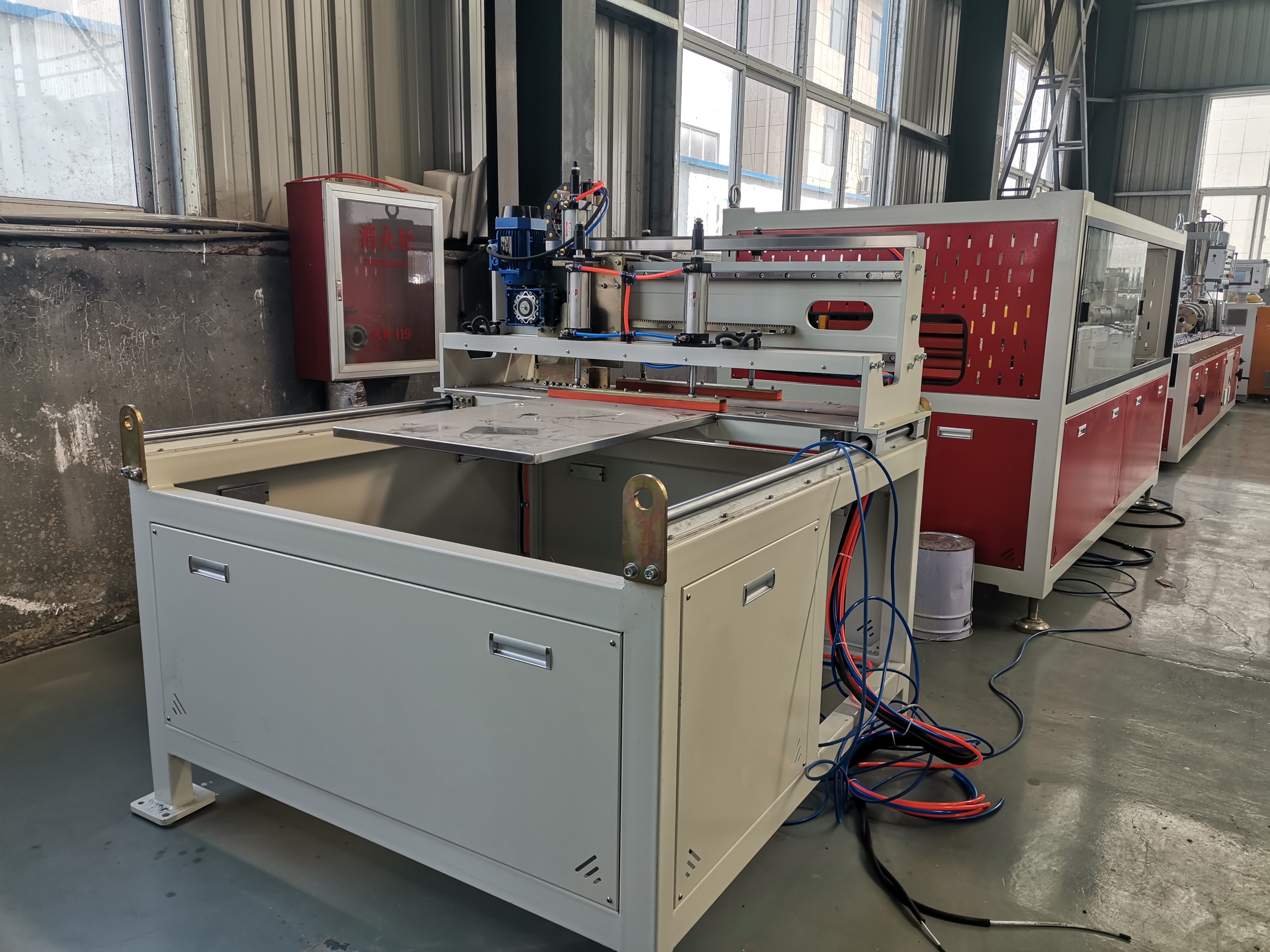

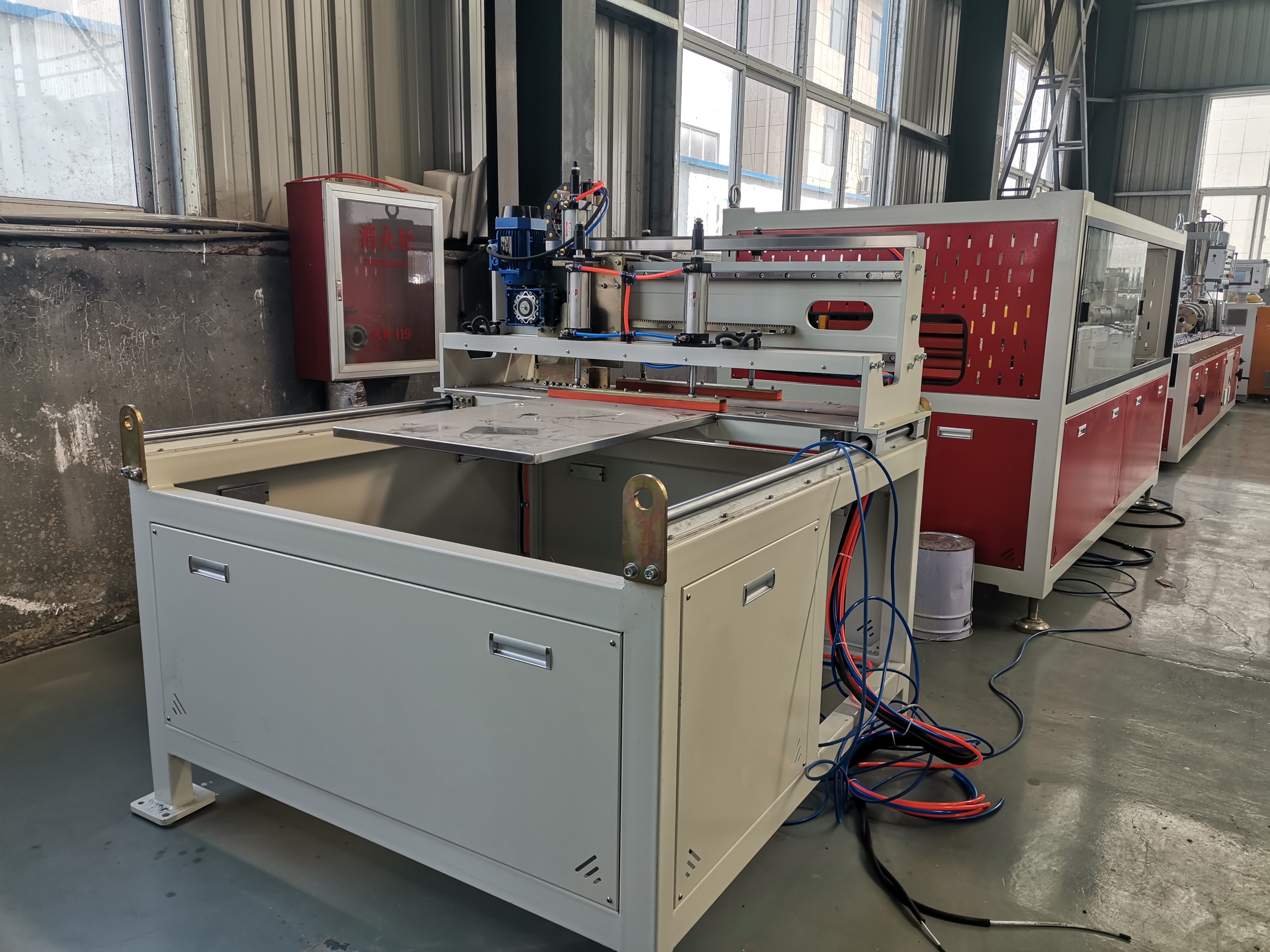

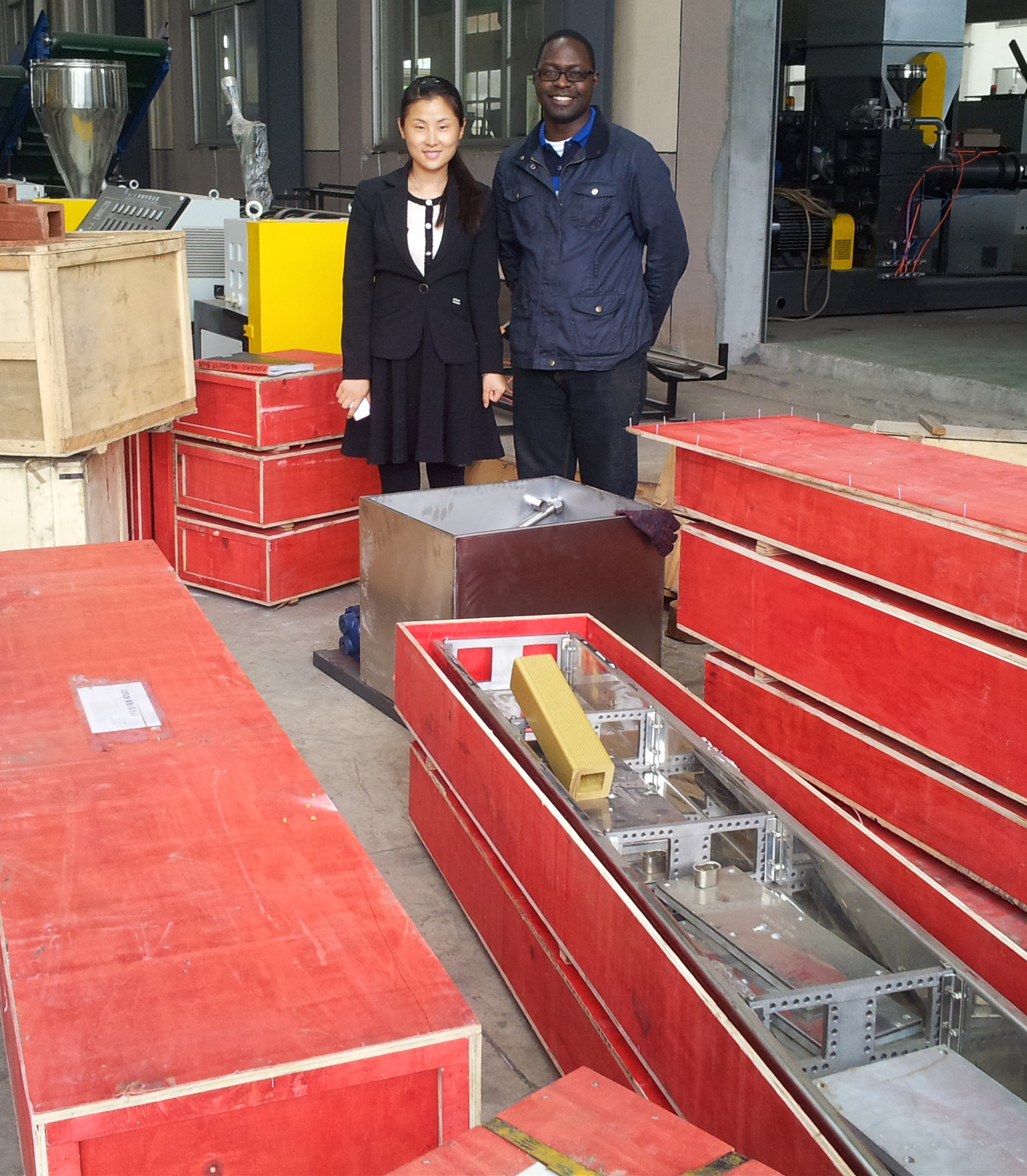

Pvc Electrical Cable Trunking Extrusion Line

plastic powder screw loader → SJZ 55/110o SJSZ65/132conical twin screw extruder →ProfileMould → Calibrator table→ Haul off machine → Cutting machine →6 metro stacker

-

PVC Wall Board Extruder Making Making

Ang PVC Wall Board Extruder Making Machine ay binubuo ng tapered twin-screw profile extrusion equipment, nilagyan ng kaukulang molds at auxiliary equipment (tulad ng vacuum setting cooling device, tractors, cutting machines, atbp.), na maaaring gamitin para sa extrusion at pagpoproseso ng iba't ibang mga pagtutukoy at mga hugis ng matitigas na PVC wall decorative panel, ceiling gusset panel at iba pang espesyal na hugis na profile.

-

Wood Plastic Composited Product Making

Pangunahing ginagamit ng PVC / WPC profile extrusion line ang PVC o UPVC o PVC+wood powder sa extruder profile tulad ng partition ng gusali, cabinet, door panel, window sill, skirting board, door edgeline, door jamb, window shutters, photo frame, mirror frame, banding gilid ng kasangkapan, frame ng pinto, bulsa ng pinto, bulsa ng bintana, profile ng column, handrail ng hagdan, floor board, panel ng cladding ng dekorasyon, muwebles, WPC pipe, atbp. Craft Flowing Chart

-

Double Screw Extruder WPC Profile machine

Ang PVC/WPC making machine ay maaaring gumawa ng lahat ng uri ng profile, halimbawa, window, door at door frame, pallet, cladding ng outdoor wall, pasilidad ng outside park, floor etc. Output profile ay Wood Plastic Composite(WPC) o Plastic UPVC.

-

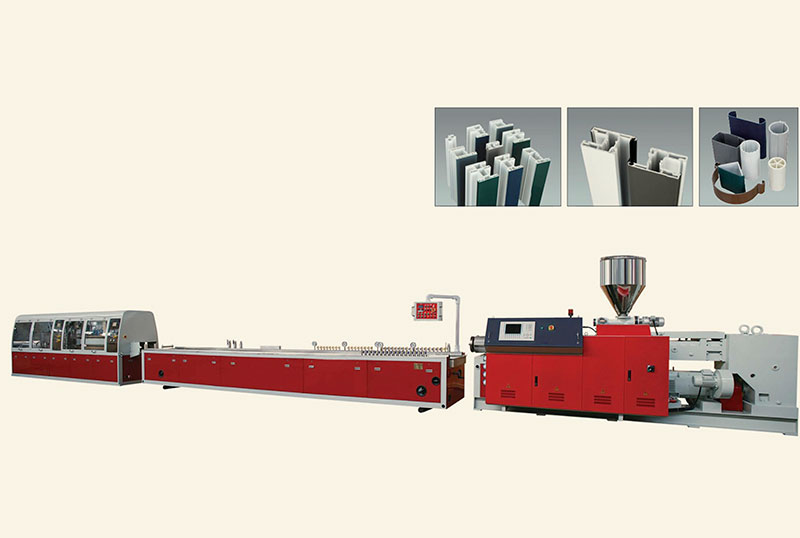

Plastic Window Door Profile Extrusion Machine

Ayon sa iyong pangangailangan, gusto naming irekomenda ang aming SJZ65/132 PVC Profile Extrusion Line.Ang extrusion line na ito ay binubuo ng SJZ65/132 Conical Twin-screw Extruder at downstream assistant machine.

-

Wood Plastic WPC door board Linya ng Produksyon

WPC PP PE PVC Wood Plastic Profile / Decking/Door Frame/ Wall Panel/Floor Fence Post Window Extruding Extruder / Extrusion Making Machine Presyo ng Pabrika

Screw Loader para sa Mixer—High Speed Mixing Unit—Screw Loader para sa Extruder—Conical twin screw extruder—Mold—Vacuum calibration machine—Traction Machine—Cutting Machine—Stacking Table

-

Wood Plastic Composite Profile Production Line

PVC WPC Door Floor Decorative Profile Board Panel Extrusion Production Line,

Double Screw Profile Extruder Ang linyang ito ng produksyon ay pangunahing ginagamit upang makagawa ng PVC profile, tulad ng Ceiling, Deck, Floor, Cornice, Plank, Windows, Door frame at board at iba pa.

Tampok:

1. Conical twin-screw extruder, na angkop para sa pagproseso ng PVC powder at WPC raw na materyales.

2. Pagbabago ng mga hulma upang makagawa ng maraming uri ng iba't ibang PVC profile.

3. Auxiliary machine: Mixing unit, Crusher, pulverize, laminating machine… -

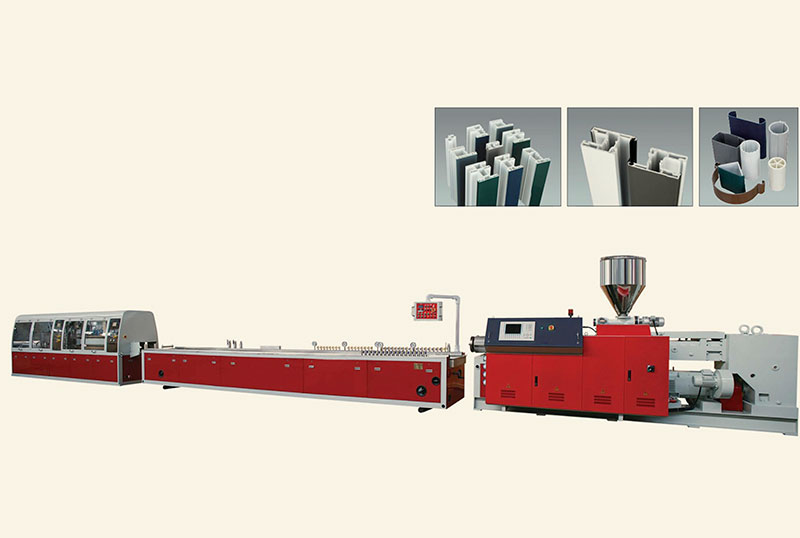

PVC Door and Window Profile Extrusion Line

High Efficiency PVC Window at Door Profile Extrusion Making Machine Production Line, PVC Profile ay may mga katangian tulad ng sound separation, sound absorption, heat separation, temperature-keeping, etc.Ang materyal ay hindi nasusunog, ito ay ligtas para sa paggamit.

Ang lahat ng mga serye ng mga produkto ay may ari-arian ng moisture proof, mildew proof, water resistance, ang vibration resistant effect nito kung mabuti.Ang lahat ng mga serye ng mga produkto ay may pag-aari ng weathering proof, ang ningning nito ay maaaring manatili magpakailanman, hindi madaling tumanda.Ang produktong ito ay magaan, imbakan at transportasyon, ang konstruksiyon ay medyo maginhawa.Ang produktong ito ay maaaring gawin gamit ang mga normal na tool para sa kahoy na materyal.Ang pagbabarena, paglalagari, pako, pagpaplano, pagbubuklod ay maaaring isagawa tulad ng kahoy na materyal.Ito ay angkop para sa thermal shaping, thermal bending at fold processing.Maaari itong welded, maaari din itong i-bonding sa iba pang materyal na PVC.Ang ibabaw ng produktong ito ay makinis, maaari itong i-print. (Linisin ang ibabaw bago i-print.)

-

Plastic PVC Electrical Cable Trunking Profile Extrusion Line

Plastic Cable Trunk Profile Extrusion Line Plastic Extrusion Machine, Plastic PVC Electrical Cable Trunking Profile Extrusion Line

>> Gamitin: Para sa produksyon ng malambot na PVC profile, matibay na PVC profile, soft-hard co-extrusion profile, foam profile extrusion, multi layer co-extrusion atbp.

>>Daloy ng Proseso: Screw Loader →cone / parallel Twin Screw Extruder/Single screw extruder → Co-extrusion machine → Mould → Calibration Table → Haul-off at Cutter → Tripping Table → Final Product Inspecting & Packing -

PET packaging strap belt production line

- Plastic PP Pet Packing Band Strap Belt Extruder Making Machine

Packing Band Making Machine

Pack Band Extruder

Plastic Pet Packing Strap Belt na Gumagawa ng Extruding Machine

Makina sa Paggawa ng Plastic Strap

Pet Strap Extrusion Machine

PET Plastic Strap Packing Belt Making Making

pet belt extrusion machine

Plastic PP Pet Packing Strap Making Line Pet Strapping Banding Belt Strip Production Machine

PP Strap Making Machine

PP Strapping Band Making Making

Plastic PP Packing Strap Line / Strapping Machine na may Murang Presyo

Strap Extrusion

Linya ng Strap - Paano naman ang output ng PET strapping band extrusion line?200kg/hr, 400kg/hr, 600kg/hr, 800kg/hr.

- Paano naman ang laki ng strap na kayang gawin ng PET strap machine?Lapad: 9-32mm;Kapal: 0.35-1.2mm;

- Paano ang tungkol sa kapangyarihan ng pag-install ng PET strap machine?215kw/285kw/352kw/900kw;

- Paano naman ang maximum tensile strength ng strap?12000N (32*1.2mm);

- Paano naman ang camber of strap?<20mm/2m;

- Paano ang tungkol sa paggamit ng PET strap?Pag-iimpake ng koton, aluminyo, kahoy, ladrilyo, mga kahon;

- Gagamitin ba ang strap para sa awtomatikong strapping tool o manual tool?pareho.

- Plastic PP Pet Packing Band Strap Belt Extruder Making Machine